Plant Modeling

3D Modelling Service helps in Plant Design. These days, 3D plant modelling services are used significantly for plant designs to improve engineering productivity and reduce overhead costs and time.

Advantages of 3D Modelling service on Plant Design:

Visualization: Ability to visualize scenarios and change according to need during the design process.

Presentation: 3D service makes it easy to design proposals or reviews by creating model renderings and animations

Review: Gives the ability to go through the 3D plant model and review any changes.

Increased productivity: 3D service-based plant models offer faster design output and more productivity than 2D.

Non-Technical - Virtual prototypes allow non-technical people to participate in the design process and give input.

Increased scope: 3D service rendered plant designs can easily incorporate the latest design changes and thus give more scope in engineering.

Predictability: 3D service-based plant models allow the scope of testing different scenarios, offer quality control, prevent errors and validate designs to reduce costs.

Physical Model Elimination: 3D service prevents the need, time and cost of physical prototype models.

Billing: 3D services based planet models gives an automatic bill of materials for more accessible procurement purpose.

Better Data Management: 3D service-based plant models gives the ability to manage, organize and design data efficiently.

Standardized detailing: 3D plant modelling and drafting practices.

Automation: Increased speed and accuracy of the design process and faster rendering for more customer satisfaction.

Forecasting Material Consumption: 3D plant modelling gives an idea of material consumption accurately and thus reduces procurement of construction material and fabrication time.

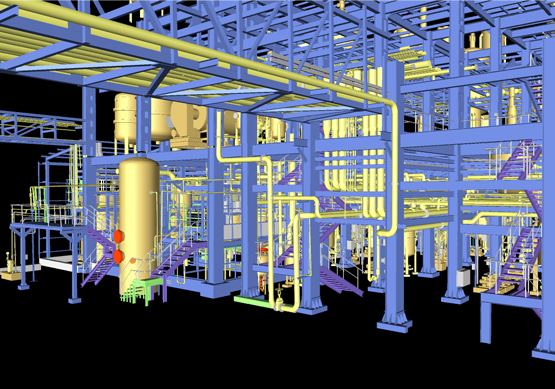

Maintain Standards: All global standards can be used for Piping 3D Model.

Data Reporting: Smart Data Report Management gives accurate billing of materials as used.

Intelligent Piping and Instrumentation Diagram can create a diagram as per process.

Reduced human resources: 3D based plant modelling reduces the workforce considerably for optimal resource consumption.

Know about the Piping and Instrumentation Diagram Quality, Sustainability, Time and Cost:

3D Model – Piping and Instrumentation Diagram Quality

It is easier to create designs with intelligent objects.

3D based plant models give better visibility, facilitate zero errors and omissions, and save time and money regardless of how many times the plant design changes.

3D based plant models simulate real-world performance, appearance and cost for the engineers.

3D Model – give sustainability and help in monitoring, managing and improving performance using 3D models.

3D Model – Time and money

Even before the plant's construction begins, engineers can visualize the entire plant and reduce design costs and conflicts practically for better efficiency and better-optimized design. 3D Pointshot, a 3D modelling service of plant design engineering, gives clients efficient and effective solutions and enables them to make correct strategic decisions by engaging in the designing process from the beginning.