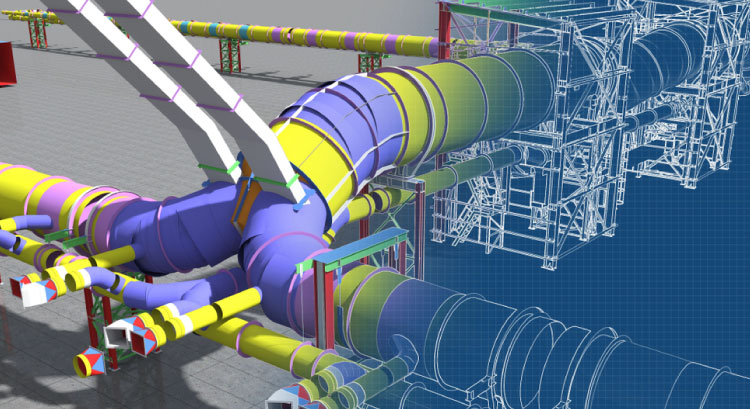

3D Plant Design Services

- 06 Oct 2021

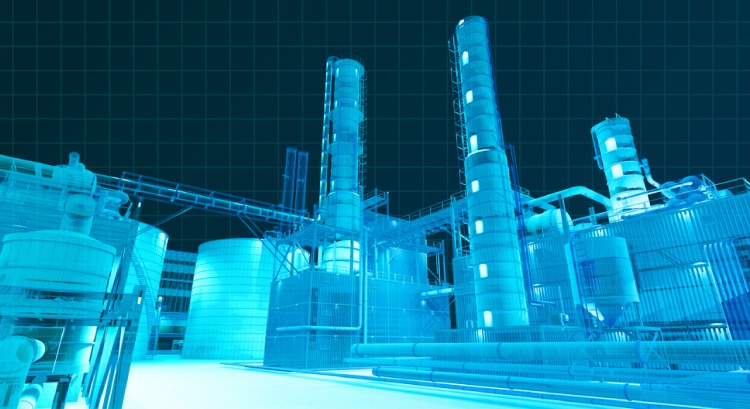

3D Plant Design Services with the help of 3d piping design software is a significant portion of engineering work, e.g. Chemicals, Oil and Gas, Power, Petrochemicals, Pulp and Paper, Refineries, and the processing industry. Various engineering companies use approximately 50 plants or piping design software throughout the world.

The current trend in the Engineering, Procurement, Construction, and owner sector is towards integrated management systems, design, manufacturing, and construction. Plant Design Solution help organizations to develop a detailed 3D model for optimized design, construction, material management, planning, and plant safety in today's plant engineering practices.

Here, we will cover the most popular tools for 3D Plant Design Services.

1. AutoCAD plant-3D by Autodesk.

2. AutoPLANT developed by BENTLEY

3. CADWorx developed by Hexagon

4. PDS- Plant design software developed by Hexagon

5. PDMS – Plant design & Management software

6. Smart® 3D – developed by Hexagon PPM

Smart® 3D is a data-centric Plant Design Solution designed to deliver mission-critical requisites. Smart 3D comes with all the resources needed to create and design plant, marine, and also has materials handling capabilities.

Benefits and features of Smart® 3D:

● Real-time Concurrent Design

● Automated Deliverables

● Intelligent Rules and Relationships

● Interoperability

● Task-based Modelling

● Undo function available.

● Offers 3D visualization tools for creating models.

2. PDMS – Plant design & Management software:

Plant Design Management System is known in the 3D Plant Design Services industry for its customization flexibility. PDMS also has additional benefits for instance it is multi-user and also multi-discipline.

PDMS software is developed by AVEVA and is a popular engineer-controlled Plant Design Solution for design, engineering, and both offshore and onshore plant construction projects. PDMS is highly customizable and the benefits of being a multi-user make it one of the most used piping software.

Benefits and Features of PDMS:

● PDMS allows the reusing of designs from incorporated components

● PDMS has smooth integration with 2D AutoCAD

● Modification of existing models is much easier in PDMS.

● PDMS runs smoothly in higher job sizes.

● A user-defined command can be created.

● On line clash detection facility available

3. PDS- Plant design software:

PDS is a comprehensive, intelligent computer-aided Plant Design Solution and it is one of the most popular 3D model piping programs used for 3D Plant Design Services throughout the world since 1980.

PDS is developed by Intergraph. PDS runs on Microsoft Windows and is compatible with most 3rd party modules and hexagon software. The software is comprehensively used in refineries, offshore facilities, power plants, petrochemical plants, chemicals, etc.

Benefits and features of PDS:

● Dynamic walkthrough for operations and maintenance personnel

● Interference checking by developing clash-free systems.

● Accurate material take-offs

● Specification driven designs and phased reviews

● Integration with Complementary Applications.

4. CADWorx developed by Hexagon:

CADWorx Plant Professional runs on the AutoCAD platform. It provides a complete package with powerful and adaptive tools that enable the quick and easy creation of brilliant 3D plant models.

CADWorx enables efficient plant design for oil and gas, fertilizers, refineries, petrochemicals, and many more.

Benefits and features of CADWorx

● Accurate piping design by referencing parametrically driven components

● Creates automatic isometrics from layouts, databases, or Isogen

● Detects clashes and collisions

● Offers real-time design status and makes bills

● Intelligent 3D Piping Design

● Equipment Library Administration

● As-builts from Point Clouds

5. Auto PLANT developed by BENTLEY:

Bentley Auto PLANT Design Solution runs on AutoCAD. Bentley Auto Plant Design software is built on object-oriented technology, yet it is easy to use and customize. It helps in creating and developing Piping models in the 3D environment of Auto PLANT.

Auto PLANT also gives interactive routing for various industries.

Additional modules that are included in Auto PLANT:

● Auto PLANT Piping

● Auto PLANT Equipment

● Auto PLANT I&W

● Auto PLANT P&ID

● Auto PLANT AutoIsogen

Benefits and features of Auto PLANT:

● Automatic Piping Isometrics with OpenPlant Isometrics Manager

● Provides data mobility upon integration with Bentley plant design.

● Access over 100 component catalogs, with example specs included

● Time and resource efficiency by scripting Auto PLANT install

● High information mobility.

6. AutoCAD Plant-3D by Autodesk:

AutoCAD Plant 3D provides 3D models of piping, support structures. AutoCAD 3D also generates isometric, and orthographic drawings. AutoCAD P&ID helps in functionality and quick generation of isometrics increases productivity, accuracy, and coordination.

Benefits and Features of AutoCAD Plant 3D:

· The AutoCAD Plant-3D comes with solid mesh modeling characteristics.

· Inclusion of modern 3D navigation tools showcases the engineering design.

· Different section planes can be developed, a cross-section of solids, side section etc.

· Render 3D models on the web without affecting the system memory.

Conclusion:

3D Plant Design Services depend on 3D modeling Plant Design Solution as this software are an inevitable part of an EPC design engineering team. The use of 3D modeling piping software tools enhances the performance of the engineering, also helps in reducing errors, and reduces work on the site, and makes the workflow very efficient.

At 3D Pointshot, we take care of every aspect of the project using the most sophisticated software to meet the project and Code requirements. This also allows us to save on engineering costs and improve on the project schedule.