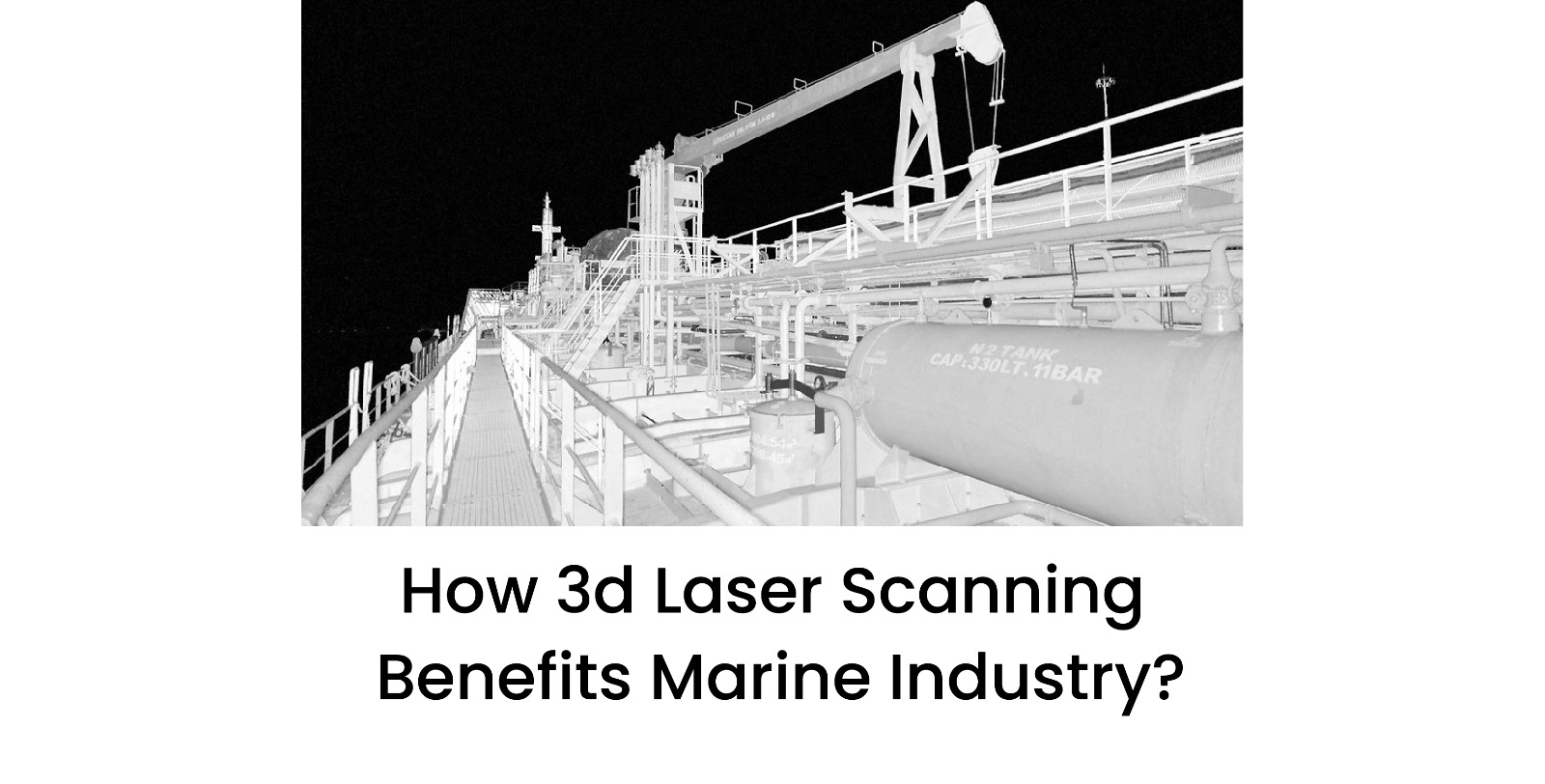

How 3d Laser Scanning Benefits Marine Industry?

- 19 Dec 2022

The marine industry desperately needs cutting-edge technologies like 3D laser scanning for a variety of new duties, even in the absence of new environmental regulations. Soon, thousands of outdated ships will require equipment upgrades, the majority of which involve traversing confined spaces. These basic arrangement portrayals may not fully reflect the current situation on a given vessel, especially one that has been around for a long and has experienced its fair share of repair yard insertions, even for owners who retain archives of original blueprints. As a result, equipment conversion is frequently time-consuming, expensive, and rife with measurement errors. It's not necessary to be that way.

Old Way Vs New Way of Marine Industry Laser Scanning

In the olden days, automotive products were made with a manual process that often used materials like wood, clay, and plastic for the design process. This made the complex functionality of the product components difficult to maintain and observe without digital systems. Still, It served the functional design purpose of creating constructive in-demand products from the scratch.

However, upon evolution and growth in the engineering sector advanced reverse engineering methods came into existence. It led to the creation of new products with improved technological features that were completely digitized and controlled based on their component's behaviour.

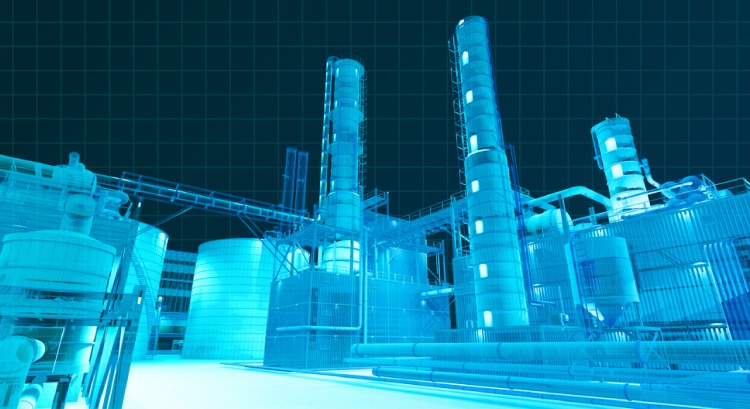

3D Laser Scanning for the Marine Industry

A more effective strategy involves marine industry Laser Scanning using a 3D laser scanner to scan ship spaces, producing a highly accurate and detailed 3D point cloud representation. Since they can take tens of millions of measurements in just a few minutes, today's high-speed laser scanners are ideal for this use. To provide appropriate coverage around the apparatus, scans are performed from multiple angles. Once registered, the scans are all placed in the same coordinate system. When done correctly, the laser scan data from the 3D scanner can be accurate to within 3 mm over distances of 10 metres.

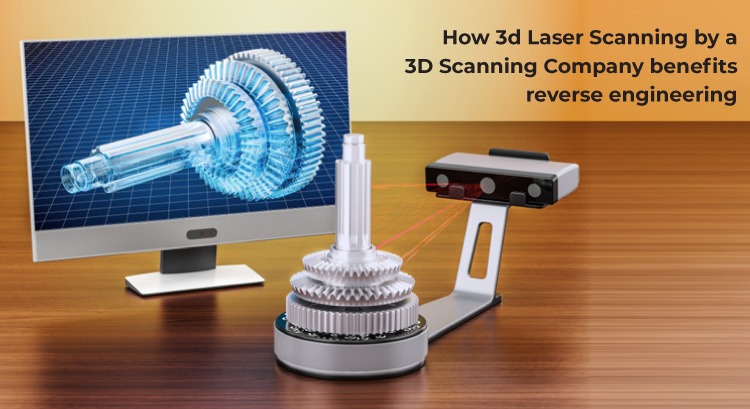

What is Reverse Engineering?

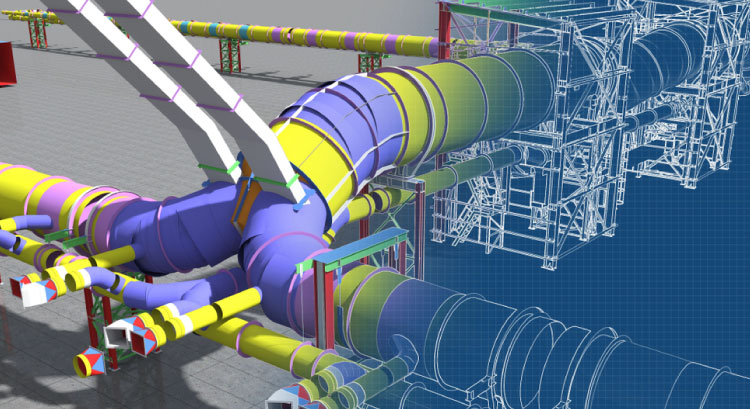

Reverse engineering is a process through which reassembling components happens to evade the need for building a product from scrap. In the past, human reverse engineers were required to properly examine components, including analyzing dimensions and acquiring measurements for accurately disassembling a product. Later, those disassembled parts were used to create a new product that saved material resources. So, to avoid the trouble of needing a reverse engineer 3d Laser Scanner was discovered.

How has 3d Laser Scanning benefited Reverse Engineering?

Reverse engineering was a time-consuming process as it required manual engineers for analyzing and disassembling a product for its component and design. However, recent advances in 3D laser scanning technology have made reverse engineering much simpler and cost-effective. It has significantly changed the whole outlook of the reverse engineering world and has provided lots of benefits

7 benefits of 3D laser scanning over the manual process of reverse engineering -

-

Eliminates the need for human resources

-

Time-saving and budget friendly

-

Accurate measurements and dimensions

-

Faster and simpler to use

-

Automated disassembling of products

-

Replaces the old traditional methods

-

Digitization of small and complex components

Conclusion

3D Laser Scanning For The Marine Industry combined with reverse engineering has given new hope for the improvement of marine engineering. The marine industry has completely changed today thanks to leading companies in India like 3D Point Shot which provide 3d Laser Scanning and Marine Industry Laser Scanning.