What’s a Digital Twin, and Why Should You Care?

- 30 Jul 2025

In today’s data-driven business world, Digital Twins are changing the way businesses function. Digital Twin modeling provides advanced ways to monitor, simulate, and improve offline, real-world systems in industries from manufacturing to smart cities. But what is a Digital Twin, and why should your business care, especially when you’re just beginning to understand the digital transformation?

This is a basic overview for someone beginning to understand Digital Twin and be more aware of Digital Twin services for their organization.

What is a Digital Twin?

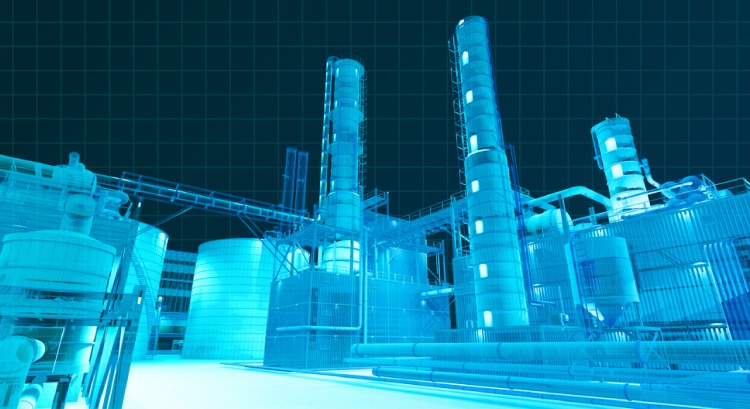

A Digital Twin is a living model of a physical object, system, or process, which constantly exhibits what is happening in the actual object, system, or process, therefore making its utilization possible for simulating scenarios, modeling possible outcomes, and supporting decisions based on the data that a digital twin could provide.

For example, a 3D Digital Twin of a factory is a living, digital representation that shows the physical layout of the factory, along with the ability to have real-time visibility into the performance of machinery, energy use, and production flow—all from a virtual dashboard.

The Process of Digital Twin Modeling

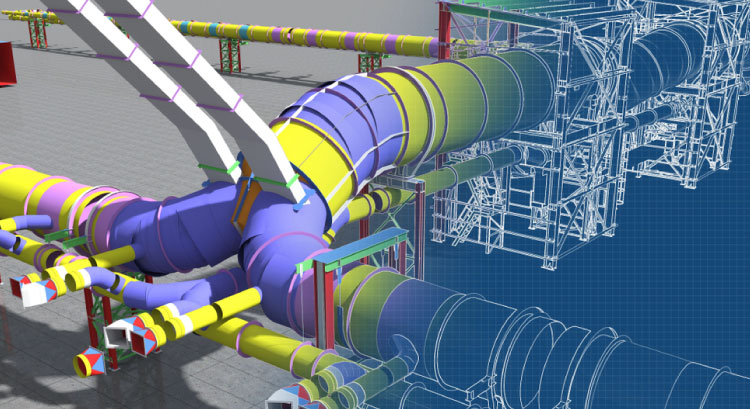

Digital twin modeling is creating the digital twins with accurate geometry, data mapping, and physical modeling. Digital twins are 3D reproduced objects; it's also the process of creating those digital models using 3D scanning, LIDAR, BIM (Building Information Modeling), etc.

Digital Twin modeling services can, when executed effectively:

> Increase operational efficiencies.

> Decrease maintenance costs

> Improve product development

> Implement predictive analytics

> Enable remote monitoring and diagnostics

What’s the Big Deal? (Especially If You Are a Beginner)

If you are a business owner, facility manager, engineer, or planner, understanding Digital Twin services is no longer an option. Here’s why:

1. Improved Decision-Making

A Digital Twin provides one source of truth. With real-time updates and simulations, decision-makers prioritize faster response times and smarter decisions free of guesswork.

2. Cost Savings

Predicting failures before they occur and simulating outcomes before intervention avoids costly downtime and wasted resources.

3. Improved Collaboration

A 3D Digital Twin allows teams, whether onsite or remotely located, to share the same digital model. This creates a platform for improved communication with reduced errors while allowing

for more efficient project workflows.

4. Scalable Solution

Model one machine or an entire smart city – Digital twin modeling services scale to fit your growing need.

What Are The Reasons for Selecting Digital Twin Modeling Services from 3D Pointshot?

3D Pointshot specializes in high-precision Digital Twin modeling, enabling your environment to become a lifelike experience. If you are looking to create a 3D Digital Twin for urban planning, infrastructure, construction, or manufacturing use, our team will provide you with customized solutions using the latest technology.

From raw scan data to fully interactive Digital Twins, we make sure our solutions have accuracy, scale, and usability, with your business objectives in mind.

Common Applications of Digital Twin Technologies

> Smart Cities: Gauge the current state of traffic, waste management, and utilities.

> Manufacturing: Increase production line efficiency and prevent equipment issues.

> Construction: Track progress, visualize changes, and manage risk.

> Healthcare: Simulate patient treatments or a hospital management system.

> Energy & Utilities: Assess the performance of assets (e.g., wind turbines, power grids).

Frequently Asked Questions (FAQs)

1. Is Digital Twin just for huge organizations?

No. Even small- or medium-sized businesses can utilize Digital Twin services, especially within the construction, manufacturing, or urban planning spaces.

2. What is the difference between a simple 3D model and a Digital Twin?

A 3D model is a static representation of something—something to visualize. A Digital Twin instead is a dynamic and data-driven representation that can be used for monitoring, analysis, and simulation.

3. What is the cost of Digital Twin modeling?

Costs vary based on the size of the assets, level of detail, and level of data to be integrated; however, you generally achieve high ROI—due to operational efficiency and risk reduction.

4. How long does it take to create a Digital Twin?

The timelines for projects will vary based on the complexity of the physical objects and the size of the asset. However, with the knowledge and experience of 3D Pointshot and our expert teams, turnaround can be reliable and consistent.

Conclusion

Business today is digital—and the future of business is digital in a way we have never known. "Digital twinning "is leading that charge. It doesn't matter if you're getting into the business or scaling; adopting Digital twin modeling has the first-mover advantage.

Digital Twin services provide insight in real-time, offering predictive analytics and process optimization that keep businesses relevant in their industries. Organizations like 3D Pointshot can provide high-level digital twin modeling services that bring your vision to a connected, scalable business.

Don't wait. Start your Digital Twin journey today and become a part of the smart business organization movement!