Advantages and Disadvantages of 3D CAD Modeling in Engineering

- 04 May 2023

Computer-aided design, or 3d cad modeling, is conceptualizing an idea using a computer. Its CAD design application is often used by experts in fields like architecture and industrial design, which rely heavily on detailed technical drawings. It's more challenging to open and start sketching than some other apps. You'll need a mix of tools and mathematical calculations to get started and make the design perfect. Because it is difficult to learn, individuals are educated to the level of experts to operate the software.

What is a computer-aided design (CAD)?

Design mockups in 2D and 3d cad modeling, a technique rooted in the 1960s. In the 1990s, software like CATIA and AutoCAD were developed, making CAD more widely available. Engineers, architects, and construction workers are the most frequent users of CAD software.

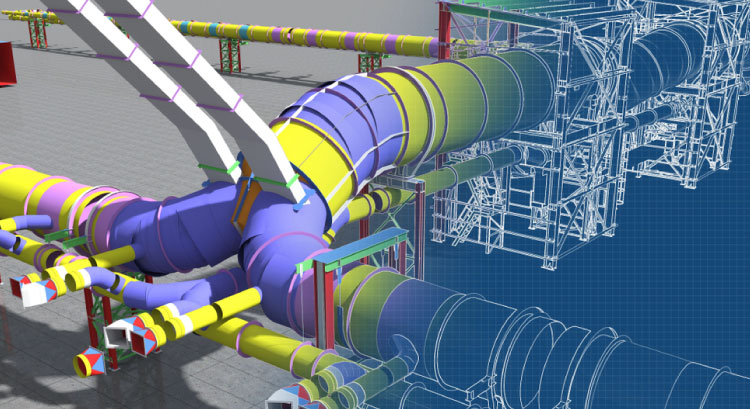

Professionals may get closer to the actual designs they see with the help of CAD. CAD eliminated the need for hand-drawn layouts and allowed infinite iterations and improvements in the final product. Engineers can create more refined designs and digitally alter them using CAD software. CAD programs can determine the interplay of several materials. When contractors add additional requirements, this function becomes more important.

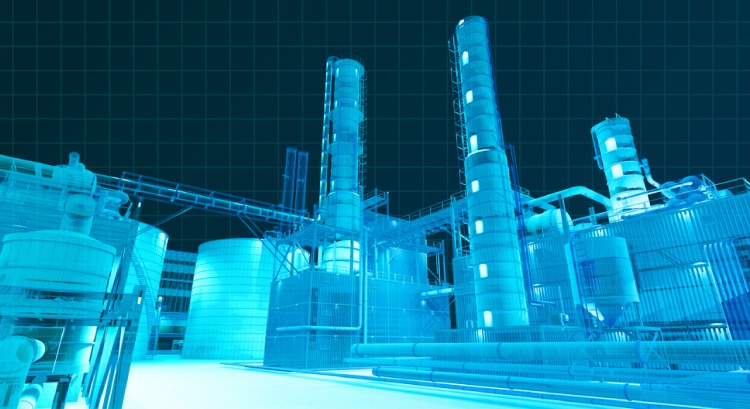

Due to its wide range of capabilities, 3d Solid Modeling software has become a standard tool in the building, architectural, and engineering industries. The evolution of computer-aided design (CAD) has altered these sectors and all activities associated with carrying out complicated project stages.

Benefits of using CAD

Time is money, and once you start using CAD, you'll find that you have more of it since you'll be able to create better, more efficient, and more exact designs in less time. You'll be freed up to concentrate on other parts of running your company.

● Less time spent on design:

With CAD, you'll discover that you need to put in much less work to create various models since the CAD program can automate so much of the process for you.

● Easily modified:

It's common to make adjustments to designs as you work on them. With 3d Solid Modeling software, you can quickly correct any mistakes and make necessary adjustments to your plans without starting from scratch.

● Reduced occurrence of errors:

Since it employs the most excellent tools, CAD software dramatically reduces the number of mistakes that may be made during the design process.

● Simple to pass on:

CAD's built-in capabilities make it easy to save and retrieve files in a form that allows for many uses and easy sharing.

● Improved precision:

Manual drawings will never match the precision that CAD software can provide. Specialized tools in CAD may evaluate your design's quality, expertise, and correctness.

● Code reuse:

With the 3d cad modeling services program, you may easily replicate sections of the code and design for use in future projects. The CAD system will monitor for design duplicates, so you won't have to worry about it happening.

Problems with Computer-Aided Design

● Verification of specifications, mechanically

With CAD software, the designer may instantly see whether their creation is up to code. In addition, CAD software lets customers see designs at an earlier level than is typically the case. By using CAM, customers may examine the development of working and partially working prototypes considerably sooner than is feasible with conventional design methods.

● Constraints with processing speed

Many computers need help to handle the demands of running CAD programs. This calls for expensive yet high-quality computer gear. CAM is only possible with high-priced, high-tech production equipment. This prohibitive investment in hardware is a fundamental drawback of CAD/CAM that prevents its broader adoption.

● The intricacy of the Software

The evolution of CAD programs has resulted in more adaptability and versatility. Unfortunately, this results in a more complicated program. Because of this elevated level of intricacy, the program is less friendly to first-time users. Another drawback of CAD/CAM is the high price tag for training employees to use the necessary software.

● Repairs and servicing

Maintenance costs for the computers and other equipment used in CAD/CAM may add up quickly. When machines or tools fail, it causes costly downtime and is inconvenient for everyone. Even if you're diligent about preventive maintenance, there will still be occasions when your vehicle breaks down despite your best efforts.

Conclusion

From the initial idea through detailed planning, design, and consultation papers, 3D CAD Engineering is an invaluable tool. Depending on the scale and complexity of the project, you may choose from a wide variety of specialized plant design and 3D modeling tools. You can take help from 3D Pointshot, the best 3d cad modeling services for more details.