How 3D Laser Scanning is helping Marine Industry

- 16 Mar 2022

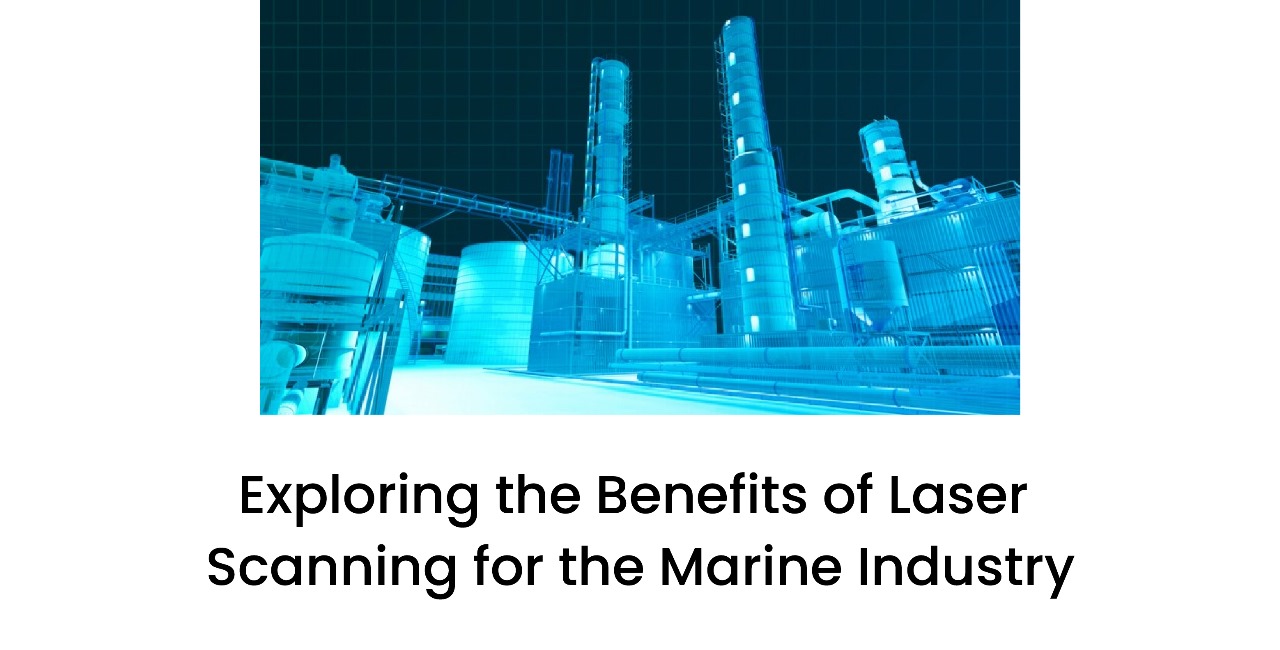

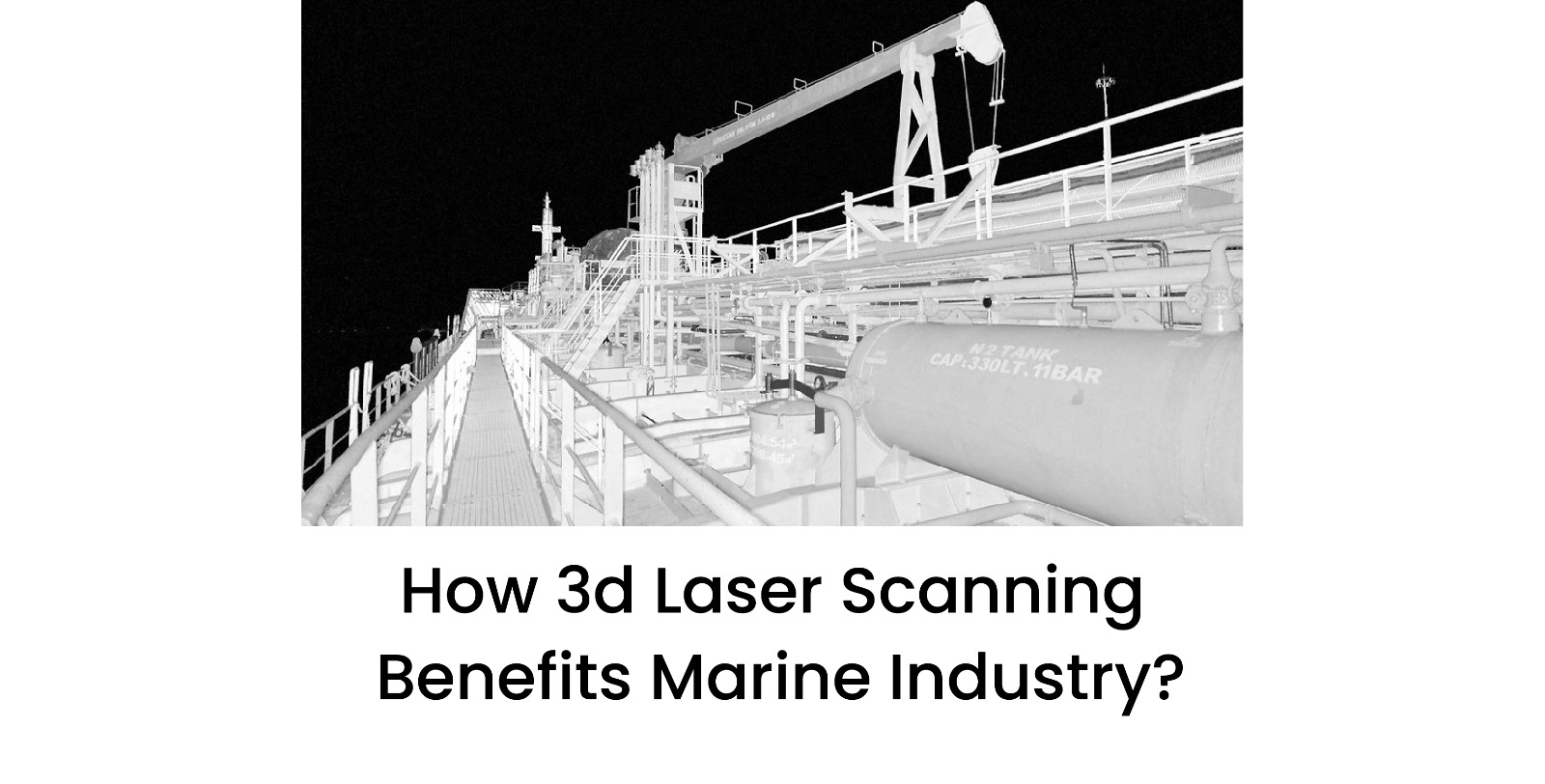

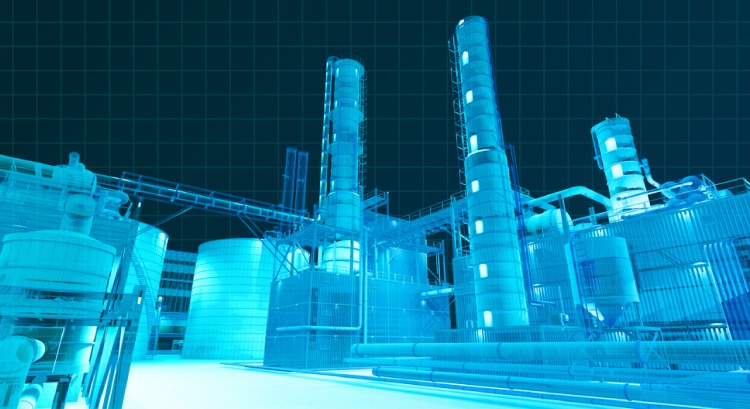

3D Laser Scanning For The Marine Industry is constantly changing. To keep up with the pace, companies need to adopt new technologies to get a competitive edge. A good example of this is 3D laser scanning. Marine Industry Laser Scanning is a technology that has been used in the marine industry for years to measure and create 3D models of boats, ships, and other vessels. It's not just used for making models though. It can also be used to measure equipment and any other physical object in a boatyard and even renovating old ships.

Thousands of old ships will soon require equipment upgrades, the majority of which will necessitate accessing tiny, cramped, and limited space locations. Even for those owners who have original designs in their archives, the general arrangement portrayals may no longer fully reflect the vessel – especially if it has been in operation for a long time and has had its share of repair yard insertions. As a result, equipment retrofits are frequently substantial, expensive, time-consuming, and prone to measurement errors. It does not have to be this. 3D Laser Scanning For The Marine Industry helps in solving all these problems with detailed 3D scanning and modeling.

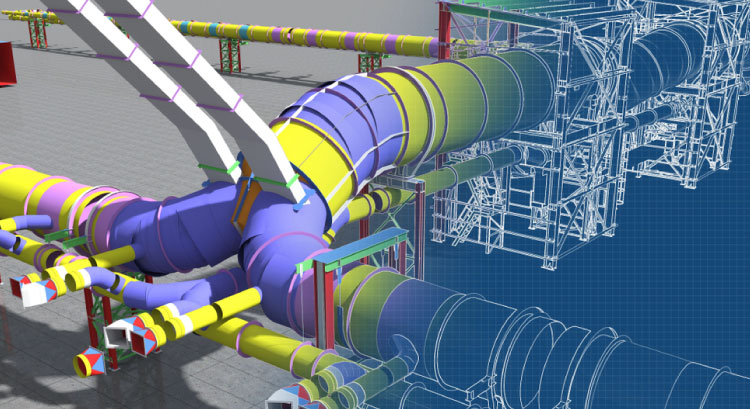

It's not just used for making models though. Marine Industry Laser Scanning can also be used to measure equipment and any other physical object in a boatyard. The contemporary approach is using a 3D laser scanner to scan ship spaces and build a highly detailed and accurate 3D point cloud model. High-speed laser scanners, which can perform tens of millions of measurements in only a few minutes, are ideal for this task. Scans are done from a variety of angles to ensure that the equipment is adequately covered. After that, the scans are registered to put them all into the same coordinate system. Scanning can be accurate to within 3 mm across 10-meter distances if done appropriately.

A 3D laser scanning for the marine industry system is a relatively new technology that is being adopted by many industries, including the marine industry. There are a number of benefits to using this technology. For example, it can be used to create accurate maps of large and complex structures, such as ship hulls. The 3D laser scanning system is also used to monitor corrosion and to evaluate hull damages. The 3D laser scanning system is a reliable, safe, and efficient way to scan a marine vessel.

Some of the key features of the Marine Industry Laser scanning are:

● It is a non-contact system

● It is fast and accurate

● It is a safe way to inspect the hull of a ship

● It can detect and measure corrosion and damages.

The Advantages of 3D Laser Scanning for the marine industry:

- While the ship is in operation, laser scanning can be done.

- Measurements are more thorough and precise than manual measurements.

- The necessity for follow-up site visits is reduced or eliminated.

- Work on the design can be done at the office or within the 3D Point Cloud Model that has been created.

- Data enables a greater number of new or replacement pipe spools to be prefabricated in the shop at a lesser cost.

- Data minimises field welds and increases the amount of bolt-up tie-ins, lowering shipyard costs and downtime.

Conclusion

3D Laser Scanning for the marine industry has become a valuable and accessible technology that will continue to make significant advancements in the shipyard and beyond.