How 3d Laser Scanning by a 3D Scanning Company benefits reverse engineering?

- 22 Oct 2022

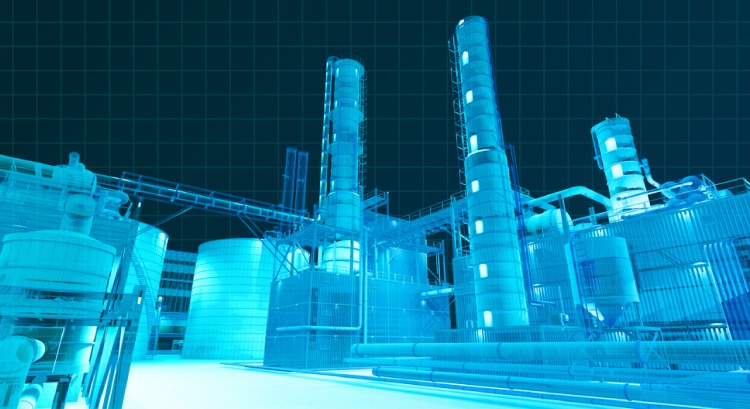

3D Scanning in India for Structural or physical reverse engineering

In the structural reverse engineering process, the product or thing is carefully examined to identify all of its visible components before the deconstruction procedure is planned. Every sub-component is then subjected to the same process. To give a thorough picture of the actual build process, all results are documented. 3d scanning Company like 3D Pointshot can help in this process.

Reverse engineering uses an existing component to disassemble it and reveal how it was made, as opposed to creating a specific component from start. When components or products have unclear build procedures and weak or insufficient design documentation, this process becomes essential.

When compared to recreating the same component from scratch, which takes a lot of time, money, and effort, reverse engineering is significantly more exact.

The Way To Go Is The 3D Reverse Engineering Process, But Why?

The problem with physical or structural reverse engineering is that not every product or component can be easily disassembled, and often the component's design prevents us from taking an exact measurement. In some cases, various subcomponents might interact with one another to create a compound component that is impossible to quantify separately. Additionally, in such circumstances, the deconstruction could not be accurate.

This necessitates the necessity to preserve the component or product in its whole and devise a method for measuring its curvature, high-density geometry, and other challenging to measure areas. Reverse engineering by a 3D scanning Company in India is quite useful in this situation.

How a 3D Scanning Company Can Help You Make Things Easier?

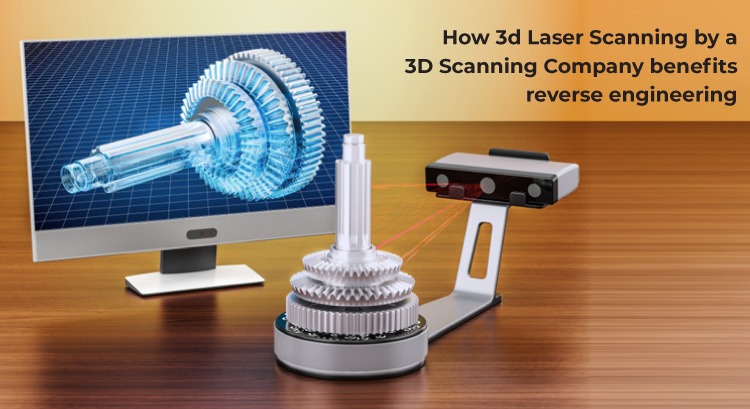

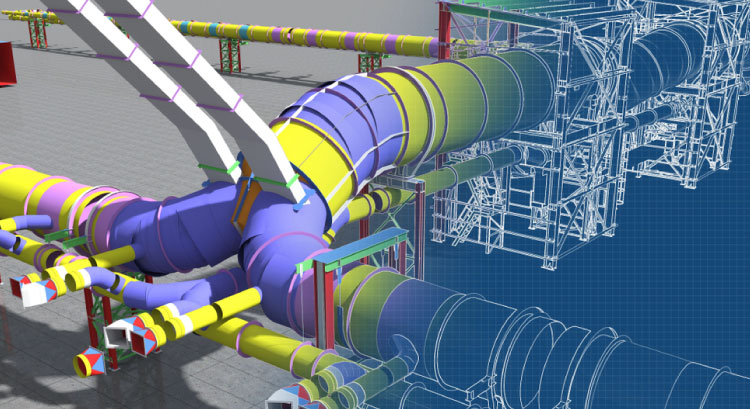

A 3D laser scanner gathers all the surface points using a precise point capture technique, and then uses software to estimate the specific shapes and dimensions of the component. You may disassemble the entire component using these 3D measurements and photos, and you can even make small adjustments to your design to make it better and more effective.

As part of reverse engineering, 3D scanning is used to measure the object to be built and reconstruct it as a 3D model. Laser scanners, industrial CT scanners, CMMs, and structured light digitizers are a few of the popular methods for 3D inspection or 3D scanning. Being able to measure otherwise difficult-to-measure objects with clear and precise dimensions makes advanced 3D laser scanning a popular technology.

Benefits of Reverse Engineering with 3D scanning Company in India

The benefits of our 3D laser scanning services for reverse engineering applications are as follows:

1. Reduces the requirement for manual deconstruction.

2. Eliminates the difficulty of measuring components that are irregularly shaped or difficult to measure.

3. Provides exact measurements and diagrams.

4. Accelerates and simplifies the reverse engineering process.

5. Allows for design adjustments.

6. Allows you to determine whether or not the altered or modified design will function.

7. Speeds up reverse engineering.

Outsource Close and Long 3D Laser Scanning in India

Outsourcing 3D Scanning in India to 3D Pointshot for 3D scanning reverse engineering, give you the freedom to precisely measure smaller components using close surface contact scanners or laser scans larger components, such as cars and buildings, using long range scanners. Reverse engineering is accelerated and made simple for our clients by our skilled team of engineers and cutting-edge 3D laser scanners.

Conclusion

3D scanning and reverse engineering is a process that creates a three-dimensional model of a product or work piece by capturing the geometry of an object using a scanner and converting it into a digital file. 3D Pointshot company 3D scanning Company in India is focused on reverse engineering for all industries and individuals.